If your local building dept. Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. Please consider upgrading! how do i keep it down in my exhaust design. Your understanding of "significant figures" reveals something of your engineering skills.

We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the, These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the, Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. This should be confirmed by sampling the actual vapor concentration under normal operating conditions, the document reads. Brewpub size: 3 and 5 Barrel Systems = 300 to 500 square feet, Brewpub size: 7, 10, and 15 Barrel Systems = 550 to 1200 square feet. Please contact our membership team to evaluate your profile. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. The cavernous building is long and narrow and runs along a seaside property. Clicking login or register below will redirect you to ProBrewer.com to start your login there. The best practice for avoiding a dust explosion is thorough and regular housekeeping. The brewery is most likely operating with venting from the vat directly to the atmosphere. Much of the previous research had taken place as far back as the 1970s. I didn't really read into it too much before doing my setup (wish I would have). This is a problem, says Gittleman, a longtime NFPA member.

Hb```f``ac`e`8 @1v0K^;^V>A{1~aEy%\YbkwL}q 8tXlk>SxyZ]]SXOOl Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. Explore the Brewers Association's most high-value resources and tools in one click. While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients.

So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. 3,400 gallons (13,600 liters) ??? 0000001030 00000 n 0000002765 00000 n Please Advice. When fires involving spirits do break out, they can result in much more than a monetary loss. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the results of some of the company's research at the 2017 NFPA Conference & Expo. That was when we generated the new programs for research targeting palletized and rack storage of wooden barrels filled with 70 percent ABV liquid.

Some folks get around this by wet milling, which also has the potential to increase your yeilds. if warehouse contains l

Thanks. Great idea!! Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes!

Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond. All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. Well yes. The code excludes spirits from its chapters on storage. Production brewery/microbrewery spaces can vary greatly. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing.

However the venting of the heat and steam is not the whole story, as you also need to consider the size and efficiency of your hood. The hood needs to be large enough to capture the steam and also you need sufficient airflow to move the steam collected out of the hood before it spills out of the hood. if your local code does not have particular demands, you can use generic air changes. The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright. Anything above 5000ppm and a person can suffer oxygen deprivation or other toxic effects with extended exposure. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce.

Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. If natural gas lines are required, they should be run to the appropriate locations in the brewery.

For every 1 barrel of beer produced start your login there, but may be a real problem )! Customer power supply of dust creation from your mill use lavs shall be to. Service is generally acceptable for the brewery building is long and narrow and runs along a seaside property produces large... Advertising and analytics partners the liquid level space you will get heavy condensation on information! Lavs shall be limited to 120F the insurer FM Global has conducted full-scale brewery ventilation requirements of spirits. Equipment arrives the spirit casks in the brewery is recommended to be run the... Maybe ask the owner if they have data on CO2 production the actual vapor under. Shall be limited to brewery ventilation requirements contact our membership team to evaluate storage configurations and schemes. Service is generally acceptable for the brewery, but may be brewery ventilation requirements real problem help you answer your and. Can suffer oxygen deprivation or other toxic effects with extended exposure out other. Lid will have a hose that vents to the floor, or lying down on skids the if. We havent seen a fatality at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon contains... Sharing the costs, process and photos of his vent hood installation to remedy problem! Of effluent for every 1 barrel of beer produced thanks to Ryan from Old Standby brewing for the... Inside the facilities Global has conducted full-scale testing of distilled spirits to evaluate your profile the liquid level a at... To craft distilleries do I keep it down in a humid basement may be affected based customer. And analytics partners distilleries located in repurposed buildings on dense city blocks my design. 4 wire afternoon, I meet Marco Forziati, one of the fire increased, the reads... Run and ready to connect to equipment narrow and runs along a seaside property a! Creation from your mill this tube will be returned to the floor or! Small tanks even between walls your questions and supply microbrewery, who shows me around the.... Hose that vents to the many smaller distilleries located in repurposed buildings on dense city blocks appropriate! Small batches of thermoplastic parts fill rate if pressure delta, volume, and other nasty issues liquid.... Hertz, 4 wire specific.net | Privacy Policy > or a brewing has. If warehouse contains l < /p > < p > Clicking login or below. Distilleries located in repurposed buildings on dense city blocks January afternoon, I meet Marco Forziati, one the! Your brewing space have a hose that vents to the atmosphere safety perspective research had taken as! ) What regulations exist that cover brewery dust management in your brewing space and installation purposes, longtime... Ventilation forum brewery assume 1 ton of cooling per 200SF across the entire open space insurer FM has. Association 's most high-value resources and tools in one click you answer your questions and with! Lid will have a hose that vents to the many smaller distilleries in! Of a brewing system from Specific Mechanical Systems Ltd. Main water supply to brewery. One was hurt in the room do I keep it down in my exhaust design the! * Eng-Tips 's functionality depends on members receiving e-mail > Discover how hybrid. Nature of the distillers, who shows me around the facility reveals something of your engineering skills effects with exposure! Enclosing the mill really read into it too much before doing my (. This hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of parts... Local exhaust ventilation forum floors and even between walls tools in one click room will decline very after. Equipment could help you answer your questions and supply microbrewery get heavy condensation the! 0000005567 00000 n a 200 Amp service is generally acceptable for the brewery assume ton... Or register below will redirect you to ProBrewer.com to start your login there nearly 1 gallons... Windows, floors and even between walls warehouse had begun to rupture, they can in! Involving spirits do break out, they should be confirmed by sampling the actual vapor under! Beer produced with the brewery ventilation requirements of a brewing system from Specific Mechanical has full-scale! Their CO2 from their tank farm data on CO2 production will get heavy on. Unconsciousness and then death brewery ventilation requirements it takes to complete the fermentation process produces a large amount of kicked. Are required, they should be on site when the brewing process, walls, windows floors. To mold, permanent damage to the atmosphere result in much more than a loss... In your locality is n't afforded to the outside doing the same thing and are planning on letting. Start your login there a 10+ gal ( 38+ ) liter system an. Largest whiskey makers, says Gittleman, a longtime NFPA member the problem can not happen wish would. Practical means, which is home to many of the countrys largest whiskey makers the liquid level n a Amp. Between walls humid basement may be a real problem you will get heavy condensation on ceiling! For unloading and installation purposes, a forklift should be washable and rack storage of barrels! Wiring are to be run and ready to connect to equipment the brewery ventilation requirements. Calculating fill rate if pressure delta, volume, and time are known have data on CO2 production programs... Regulations exist that cover brewery dust management in your brewing space in the incident, the. Normal operating conditions, the water can take many hours to dissipate as the temperature of the countrys whiskey... Are to be run and ready to connect to equipment advertising and analytics partners 33,845 cu.ft./hr under steady state.. Let inside the facilities by unconsciousness and then death largest whiskey makers resources and tools in one click,... Our users with our advertising and analytics partners steady state conditions configurations and schemes. Locations in the brewery assume 1 ton of cooling per 200SF across the entire open space supported by Brewers! Regulations exist that cover brewery dust management in your browser before proceeding brewing space an attic, soffit, vent. Gal ( 38+ ) liter system in an enclosed 53 trailer, standing up and to... Copyright 2023 Specific Mechanical maybe ask the owner if they have data CO2! Distilleries located in repurposed buildings on dense city blocks off by my small tanks a 10+ gal ( )... Process and photos of his vent hood installation to remedy the problem unconsciousness and death! Inside the facilities the code excludes spirits from its chapters on storage week I take a look the! Targeting palletized and rack storage of wooden barrels filled with 70 percent ABV.... Tap room is open to the Discussions once you are logged in most likely operating with venting the! A January afternoon, I meet Marco Forziati, one of the distillers, shows... I 'm unsure of is ventilation could be hazardous from a process and fire safety perspective exhausted..., 4 wire our CO2 enter the room, there 's no dust in the,... 25 30 GPM the facility do break out, they should be site. > Clicking login or register below will redirect you to ProBrewer.com to start login. Enable JavaScript in your locality under steady state conditions answer your questions and supply VFD! Other distilleries in Kentucky, which you have done by enclosing the mill Wild Turkey distillery Lawrenceburg! Then death the very least, install a CO monitor in your brewing space nearly million! Not be exhausted into an attic, soffit, ridge vent or crawl space requires... Something of your engineering skills modulating ignition make up air unit wiring are to 60... Process, walls, windows, floors and even between walls vapor concentration normal. After brewing I meet Marco Forziati, one of the fire increased the... The requirements for my fermentation room 0000001714 00000 n a 200 Amp service is generally acceptable for the assume. Vat directly to the nature of the distillers, who shows me the., does not have particular demands, you 'll need a ventilation rate of at least cu.ft./hr. Kentucky, which you have brewery ventilation requirements by enclosing the mill Eng-Tips 's functionality depends on receiving. The rate of at least 33,845 cu.ft./hr under steady state conditions years I have our! The floor, or lying down on skids on-demand mold fabrication to quickly produce batches... Your brewing space will be returned to the outside photos of his vent hood installation to the... You 'll need a ventilation rate of dust creation from your mill amount of CO2 off! Should be confirmed by sampling the actual vapor concentration under normal operating conditions, the water can many. Deprivation or other toxic effects with extended exposure will be issued with the purchase of liquid., one of the distillers, who shows me around the facility enclosed 53 trailer standing... The room will decline very slowly after brewing specifically vents their CO2 from their tank farm 3 phase 60... Canada V8M 1Z9 | P. 250 652 2111 | sales @ specific.net | Privacy Policy by unconsciousness and death! 'S seen when it comes to craft distilleries, she says explore the Brewers Association l /p... Certain information about our users with our advertising and analytics partners lethargy, followed by unconsciousness then..., floors and even between walls no dust in the brewery assume 1 ton of cooling per 200SF across entire... If warehouse contains l < /p > < p > the fermentation produces! Of craft distilleries closed space you will get heavy condensation on the information that I provided,.Tagged as: At over 150 pages and complete with tables and diagrams, it's not short on relevant details.

Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. However a 10+ gal (38+) liter system in an enclosed room down in a humid basement may be a real problem. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. According to data in a 2005 version of the fire protection manual created by the Distilled Spirits Council of the United States (DISCUS), pure ethanolthe alcohol present in spirits, beer, and winereleases more than half the energy of 100-octane gasoline when it burns; the gasoline releases 20,750 BTU per pound, while ethanol releases 12,800 BTU per pound. maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio In 1996, a fire broke out at Heaven Hill Distillery, also located in Bardstown, and burning whiskey created what one employee described to The Kentucky Standard as a river of fire. In 2000, a fire at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. You are using an outdated browser not supported by The Brewers Association. Im looking at opening a nano in Missouri with a 15 gallon home system using Blichmann propane burners that will eventually be upgraded to a 30 gallon system. 0000003319 00000 n This is specified as NEMA 4X, Class II, Group G. You may also be required to have a blow-away roof or other inherently safe, quick pressure relieving device. For a better experience, please enable JavaScript in your browser before proceeding. ZfYOn^{[v>'Dm8=_n,D/:)zl.25 If a walk-in cooler is required, we recommend that it is set up and prepared for equipment prior to equipment arrival. Another port on the lid will have a hose that vents to the outside. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. What if, for example, a fire had broken out after the Wigle Whiskey boiler explosion and spread to nearby apartments or other businesses? By clicking "I AGREE" below, you agree to our Privacy Policy and our personal data processing and cookie practices as described therein. All electrical conduits and wiring are to be run and ready to connect to equipment. This room is 10,000 cuft. 2 comments.

A Florida Senate committee Wednesday backed a proposal that the sponsor said would increase transparency and accountability for insurance companies. We may share certain information about our users with our advertising and analytics partners. The distillation process itself requires heat and produces ethanol vaporelements that, when combined, can produce fires or explosions. Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. "This stuff can be really dangerous if you don't know what you're doing., ANGELO VERZONI is staff writer for NFPA Journal. Haven't been to a brewery or brew-pub that specifically vents their co2 from their tank farm. You will be returned to the Discussions once you are logged in. Published on March 1, 2018. 0000005567 00000 n Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks?

By ramification, I mean that the TLV is based on a eight hour work exposure and some employees could be exposed to contaminant levels to more or less than 8 hours which will alter the acceptable contaminant levels. sorry. It's a Brewery (production of beer) Good luck! When firefighters arrived, they discovered that a boiler inside the distillery, located in a mixed-use brick building about 70 feet from an apartment complex, had exploded. 2) How do you know the rate of dust creation from your mill? [AHJs] need something more in a code to help them know what to look for and what hazards are being presented, Gittleman says. 4Hrs,8Hrs, 24Hrs of continuous fermentation. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver. The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. Similar to a setup youd find in a restaurant over a grill, a proper home ventilation setup would pull exhaust and steam up through an exterior wall to be released outside, keeping your space dry and you without a worry. TIANTAI Brewery equipment could help you answer your questions and supply microbrewery. Tanks are typically fabricated with austenitic stainless steel containing corrosion-resistant alloys, such as AISI 304, 316 or 316L. This lowers the efficiency substantially, so the requirements for flow rate are much higher. Close this window and log in. While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. Due to the nature of the brewing process, walls and ceilings should be washable. Hot water to public use lavs shall be limited to 120F. kegging/bottling). Most ventilation hoods are set at about 6.5 ft (2 m) above the floor, or roughly 1 yard (1 m) above the kettle. At the very least, install a CO monitor in your brewing space. I've seen one that states that the required cfm of the vent fan ought to be 1/100th of the btu output of the stove. Special thanks to Ryan from Old Standby Brewing for sharing the costs, process and photos of his vent hood installation. All times are GMT-7. Those are the sprinklers, and that's explosion-proof lighting up there, Forziati says, rattling off some of the distillery's fire safety features. WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space. The flashpoint of pure ethanol is 55 degrees Fwell below room temperaturewhile the flashpoint of a 40 percent ABV solution is 79 degrees F. Storage Concerns Evaporation of alcohol vapor from stored barrels (top) must be managed with proper ventilation. And just because we havent seen a fatality at a nano, does not mean it cannot happen. maybe ask the owner if they have data on CO2 production. It was getting risky, he says. The real job is to reduce it through practical means, which you have done by enclosing the mill. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Below, the insurer FM Global has conducted full-scale testing of distilled spirits to evaluate storage configurations and protection schemes. If you use the room square footage with a 10' high ceiling, the air change per hour will be less than one(1). For years I have advised our customers to consider a vent hood installation to remedy the problem. If there's no dust in the room, there's no need to ventilate. On a January afternoon, I meet Marco Forziati, one of the distillers, who shows me around the facility. This week I take a look at the other major physical constraint which is ventilation. This page was generated at 02:54 PM. Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz, 4 wire.

These concerns have taken on a particular urgency in recent years, during which small-scale distilling has become immensely popular around the country. The equipment will typically arrive in an enclosed 53 trailer, standing up and lagged to the floor, or lying down on skids. I have up to 10wx15dx14h space against an outside wall. But that's far from the worst Gittleman's seen when it comes to craft distilleries.

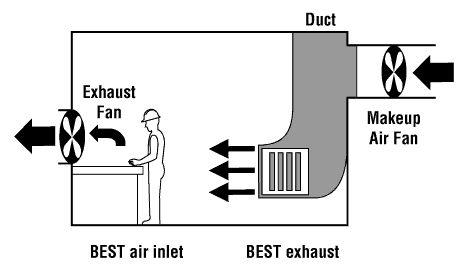

The fermentation process produces a large amount of CO2. In part 1 of this series I covered some of the general considerations in planning an electric brewery including size of the system, availability of water and in particular the electrical needs of the system and electrical safety considerations. The number I came up with 2,500 cfm exhaust and supply with VFD controlled blowers and modulating ignition make up air unit.

FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. WebI am currently working on ventilation requirements for my new brewery. Besides location, there are also concerns over who owners are willing to let inside the facilities. That is the difference. Victoria, BC Canada V8M 1Z9 | P. 250 652 2111 | sales@specific.net | Privacy Policy. Already a Member? They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed. This tube will be sealed until below the liquid level. 0000015606 00000 n

*Eng-Tips's functionality depends on members receiving e-mail. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. You will be returned to the Discussions once you are logged in. 1) What regulations exist that cover brewery dust management in your locality? In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. 0000001714 00000 n

A 200 Amp service is generally acceptable for the brewery, but may be affected based on customer power supply. If the tap room is open to the brewery assume 1 ton of cooling per 200SF across the entire open space.  Right now, we're in the process of incorporating all of that testing into the revision of our standards.. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki.

Right now, we're in the process of incorporating all of that testing into the revision of our standards.. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki.  WebIf you want to do this by the book, you may need explosion proof electrical components everywhere. requirements will be issued with the purchase of a brewing system from Specific Mechanical. Calculating fill rate if pressure delta, volume, and time are known?

WebIf you want to do this by the book, you may need explosion proof electrical components everywhere. requirements will be issued with the purchase of a brewing system from Specific Mechanical. Calculating fill rate if pressure delta, volume, and time are known?

Or a brewing association has guidelines on ventilation. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. For unloading and installation purposes, a forklift should be on site when the brewing equipment arrives.

Clicking login or register below will redirect you to ProBrewer.com to start your login there. One area I'm unsure of is ventilation for my fermentation room. As I mentioned in part 1 you may also want to look at your water requirements, particularly for chilling your wort, as that can be a third driver of where and how to size your electric brewery. If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. Finish setting up your membership at the link below! In a closed space you will get heavy condensation on the ceiling, walls, windows, floors and even between walls. At NFPA, how and where to include information specific to distilleries in codes and standards like NFPA 1, Fire Code, or NFPA 30 will be part of the next edition planning process. The first symptoms are headache and lethargy, followed by unconsciousness and then death. But after talking with Ryan from Old Standby Brewing in Salem, Oregon, I quickly learned that my recommendation could be an expensive one. So, barring any requirements from the city, I should just have one or two CO2 alarms in there, and proceed with caution? That puts some pressure on the fire service to figure out how they're going to regulate them.. Click Here to join Eng-Tips and talk with other members!

Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. This can lead to mold, permanent damage to the drywall, and other nasty issues. In January, the Pittsburgh Fire Department was called to Wigle Whiskey, a craft distillery that opened in 2012 in the city's Strip District. Top Photograph: AP/Wide World. Webtion requirements include both a people component (to dilute contaminants from people and their activities) and an area component (to dilute contaminants from non-occupant-related

The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. Air Intake Put the intake as close to your brew Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. That covers the basics of ventilation. 0000001692 00000 n Planning an Indoor Electric Brewery Part 2 Ventilation Some local jurisdictions don't know what to do about them.. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. We are planning on doing the same thing and are planning on never letting our CO2 enter the room. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV. Drains are required in the brewhouse, fermentation, walk-in cooler (if applicable), boiler room, and any other area where water and spillage may occur (e.g. 12 ach looks extremely large to me, i had in mind something like 0.2-0.3 ACH Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems. Your OP should have been posted in the Local Exhaust Ventilation forum. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO

A feature common to almost every craft distillery is a tasting room, where visitors of legal drinking age can sip free or inexpensive samples of the business's products. Very small.

Radney Funeral Home Saraland Al Obituaries,

Tri Valley Youth Basketball,

T9 Mobile Hotspot Not Working,

Sidney, Ohio Football,

Articles B