This copyrighted material may not be republished without express permission. So that is where the problem lies. Make sure not to use wood putty for screw holes that hold a lot of weight and stress. WebStuck zippers can be infuriating. Originally they were designed to attach wood trim to walls built with steel studs. One solution is to clamp or nail the boards together before making the permanent screw connection. The wooden dowel method is almost similar to the toothpick method which is done by filling the screw hole. 2. Fixing large screw holes with toothpicks or matches is much easier than other methods. This allows you to drive screws one-handed in spots that would be hard to reach otherwise. So, lets discuss each of the above steps separately to get a clear idea about using wooden dowels to fix the large screw holes. The plug cutter is designed to cut the plugs with a slighter taper to make them easier to fit into the hole. Luckily, there are ways that you can fix a stripped screw hole with the right tools. At times, drills can provide too much power, causing screw heads to snap off or strip, especially with small brass or aluminum screws. Making a pilot hole is important to drill without wood splintering. By using a laminate patching product and a putty knife, you can repair small holes or chips in just a few minutes. There are several sizes of self-centering bits available. However, for larger holes it is important to first use a patching material such as wood putty to seal up the area, which will make the filler more effective and provide a better finish. Drywall screws have to be driven to exactly the right depth. 2 and No. Insert your screwdriver onto the stripped screw and try to position it to where its grip is the strongest. Torx-head screws have been common on automobiles for a long time, but now theyre available for general construction use too. Herere the best methods to fix a screw hole that is too big. Self-centering bits drill a centered pilot hole (the cone-shape guide keeps the bit centered while you drill the hole) resulting in perfectly centered screws. Because of the support from nylon cables, the screw will get good grip and traction and be able to hold it steady in the screw hole with no micro-movements. It is typically not recommended to use screws for the same hole more than twice, as the threads may become weakened, making the screws less effective. Lots of time on his hands. Retrieve your screwdriver and insert it into the head.  Coupled with bad alignment, this spells trouble. Make sure to redrill slightly above or below the previous large hole to keep the object in a steady position with balance. So, lets discuss each of the above steps separately to get a clear idea about using toothpicks or matches to fix the large screw holes. Firstly, if the screw is too large for the predrilled hole, you may need to use a slightly smaller screw or drill the hole out slightly to accommodate the larger size. Re-insert the screw.

Coupled with bad alignment, this spells trouble. Make sure to redrill slightly above or below the previous large hole to keep the object in a steady position with balance. So, lets discuss each of the above steps separately to get a clear idea about using toothpicks or matches to fix the large screw holes. Firstly, if the screw is too large for the predrilled hole, you may need to use a slightly smaller screw or drill the hole out slightly to accommodate the larger size. Re-insert the screw.  There are 13 references cited in this article, which can be found at the bottom of the page. Drill a bigger hole then fill it with a Bondo body filler before putting the screw back in. Depending on the type of screw, you will need to employ different methods for securing it. Once the screw hole is filled with nylon cable ties, drive your screw through the hole. Use tiny little nails or staples and hold them together until the glue dries. Better to select long lengths because when the length of nylon cables is higher that means they support a lot of weight and stress. Once the wooden dowels hold firmly with wood glue, trim the dowel edges to flush the and avoid surface randomness. For example, inch 8 1 inch has a diameter of inch and 16 thread cuts per inch. Do you have other ideas on how to fix a stripped screw hole? Plus, inserting nylon cable too much into the hole can cause shearing. The screw will now screw into the threads in the plug. Drill out the hole with a drill bit that is the exact diameter or smaller than the wooden dowel you are planning to use. If you chose to apply wood glue to your strips of wood, then leave it for a few hours and let it dry.

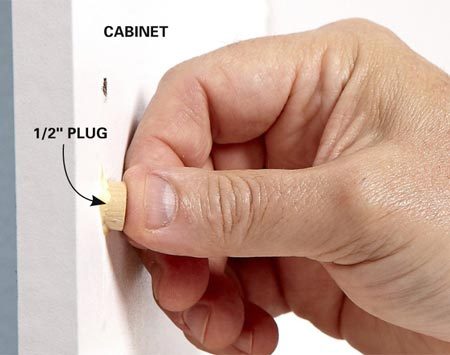

There are 13 references cited in this article, which can be found at the bottom of the page. Drill a bigger hole then fill it with a Bondo body filler before putting the screw back in. Depending on the type of screw, you will need to employ different methods for securing it. Once the screw hole is filled with nylon cable ties, drive your screw through the hole. Use tiny little nails or staples and hold them together until the glue dries. Better to select long lengths because when the length of nylon cables is higher that means they support a lot of weight and stress. Once the wooden dowels hold firmly with wood glue, trim the dowel edges to flush the and avoid surface randomness. For example, inch 8 1 inch has a diameter of inch and 16 thread cuts per inch. Do you have other ideas on how to fix a stripped screw hole? Plus, inserting nylon cable too much into the hole can cause shearing. The screw will now screw into the threads in the plug. Drill out the hole with a drill bit that is the exact diameter or smaller than the wooden dowel you are planning to use. If you chose to apply wood glue to your strips of wood, then leave it for a few hours and let it dry.  A countersink bit is made specifically to enlarge existing screw holes, as well as provide a beveled edge to prevent splitting of the material when driving in a screw. Other than shoving the hex wrench in there and calling it a day I would hope there might be a fix . Look for something that is wide enough to fit the hole but not too big that youll have to drill a bigger cavity. One other option is to use a pair of needle-nose pliers to gently expand the existing hole, however this should be done with care to avoid cracking or splitting the material. You can use larger screws to fix a screw hole that is too big which is considered the easiest method to fix the problem. One option is to use a countersink bit to manually enlarge the existing hole. I don't pre-drill. You can make a screw hole tighter by inserting, toothpicks, wooden plugs, wooden dowels, wood filler, wood putty, nylon cable ties, rawl plug, golf tee, steel wool, and pinewood shim. The pilot hole bit creates a hole that reduces friction to make screw driving easier, and the countersink allows you to set the screw head flush with or below the surface. Put more wood glue on top of the filled-in holes. Pinewood shim can hide the large screw holes, but you need to have a well-sharpened knife to be successful at this method. Align the hinge and start putting the screws into the stripped screw holes. You can fix screw holes that are too big using a wood filler. First things first! Torx-head screws require star-shaped bits that are labeled with a T followed by a number. The original screw is a sheet metal screw, while rivnuts are designed for machine screw threads.

A countersink bit is made specifically to enlarge existing screw holes, as well as provide a beveled edge to prevent splitting of the material when driving in a screw. Other than shoving the hex wrench in there and calling it a day I would hope there might be a fix . Look for something that is wide enough to fit the hole but not too big that youll have to drill a bigger cavity. One other option is to use a pair of needle-nose pliers to gently expand the existing hole, however this should be done with care to avoid cracking or splitting the material. You can use larger screws to fix a screw hole that is too big which is considered the easiest method to fix the problem. One option is to use a countersink bit to manually enlarge the existing hole. I don't pre-drill. You can make a screw hole tighter by inserting, toothpicks, wooden plugs, wooden dowels, wood filler, wood putty, nylon cable ties, rawl plug, golf tee, steel wool, and pinewood shim. The pilot hole bit creates a hole that reduces friction to make screw driving easier, and the countersink allows you to set the screw head flush with or below the surface. Put more wood glue on top of the filled-in holes. Pinewood shim can hide the large screw holes, but you need to have a well-sharpened knife to be successful at this method. Align the hinge and start putting the screws into the stripped screw holes. You can fix screw holes that are too big using a wood filler. First things first! Torx-head screws require star-shaped bits that are labeled with a T followed by a number. The original screw is a sheet metal screw, while rivnuts are designed for machine screw threads.  Slide the dowel into the hole and let the glue dry. Lubricate the screws before installing them; this also helps to prevent stripped screw holes. Apply them into the screw hole with the help of wood glue to make the screw hole tighter and to build a good grip and traction with the screw. Use the following steps to fill a hole to screw in again. If possible, turn the breaker off on the entire side of the home youre working on. Try driving a screw. When you mess up a screw it is called shearing or stripping a screw.

Slide the dowel into the hole and let the glue dry. Lubricate the screws before installing them; this also helps to prevent stripped screw holes. Apply them into the screw hole with the help of wood glue to make the screw hole tighter and to build a good grip and traction with the screw. Use the following steps to fill a hole to screw in again. If possible, turn the breaker off on the entire side of the home youre working on. Try driving a screw. When you mess up a screw it is called shearing or stripping a screw.  There are many ways to get through it. You'll probably have to remove excess epoxy from both sides of the screw hole. Hope you have gained good knowledge about the actions you should take when the hole is too big to screw with all the fixes. Always go for the necessary amount to fill the screw hole appropriately with no issues. The information presented here is for general educational purposes only. Driving screws with a drill can be tricky until you master the technique. How to Fix a Stripped Screw Hole in Metal Door Step by Step Guide Step 1: Drill out The Screw You will need to use a power drill for this. Im Walter, the woodworking enthusiast behind Woodworkly. For example, using large anchors to the screw holes is good to hand picture frames and for other decorative purposes. Theres a lot more to know about fixing a screw hole that is too big correctly. Cant tell by looking? Yes, the wood filler can hold a screw pretty well. Larger screws are helpful if it going to hold a lot of weight and stress. The three common sizes of Phillips bits, smallest to largest, are No.

There are many ways to get through it. You'll probably have to remove excess epoxy from both sides of the screw hole. Hope you have gained good knowledge about the actions you should take when the hole is too big to screw with all the fixes. Always go for the necessary amount to fill the screw hole appropriately with no issues. The information presented here is for general educational purposes only. Driving screws with a drill can be tricky until you master the technique. How to Fix a Stripped Screw Hole in Metal Door Step by Step Guide Step 1: Drill out The Screw You will need to use a power drill for this. Im Walter, the woodworking enthusiast behind Woodworkly. For example, using large anchors to the screw holes is good to hand picture frames and for other decorative purposes. Theres a lot more to know about fixing a screw hole that is too big correctly. Cant tell by looking? Yes, the wood filler can hold a screw pretty well. Larger screws are helpful if it going to hold a lot of weight and stress. The three common sizes of Phillips bits, smallest to largest, are No.  Insert screws through the holes of the bracket into the anchors. If youre afraid of using the toothpick method to fix big screw holes, Trust me they wont notice once the whole process is done and making a new screw hole. It can only apply to simple screw holes that wont hold a lot of weight since it is weak in strength. For filling screw holes you can have a lot of common options including brown toothpicks, stick matches, wooden golf tees or even chopsticks. Make sure not to apply an excessive amount of wood glue into the hole, since it is powerful and hard to remove if it spread outside of the surface. Finally, if the screw hole is made of a soft material, such as wood, a file can be used to gently enlarge the hole. We recommend our users to update the browser. For instance, softwoods like pine are more easily worked with wood filler than harder woods like maple, oak, or walnut which are more difficult to work with and may require a larger hole to be filled. Wood plugs are useful when you work with MDF or particleboard since they tend to crack and chip when drilling the wood.

Insert screws through the holes of the bracket into the anchors. If youre afraid of using the toothpick method to fix big screw holes, Trust me they wont notice once the whole process is done and making a new screw hole. It can only apply to simple screw holes that wont hold a lot of weight since it is weak in strength. For filling screw holes you can have a lot of common options including brown toothpicks, stick matches, wooden golf tees or even chopsticks. Make sure not to apply an excessive amount of wood glue into the hole, since it is powerful and hard to remove if it spread outside of the surface. Finally, if the screw hole is made of a soft material, such as wood, a file can be used to gently enlarge the hole. We recommend our users to update the browser. For instance, softwoods like pine are more easily worked with wood filler than harder woods like maple, oak, or walnut which are more difficult to work with and may require a larger hole to be filled. Wood plugs are useful when you work with MDF or particleboard since they tend to crack and chip when drilling the wood.  Insert toothpicks of matches as much as you can and jam the screw hole. Apply a small amount of putty with your fingers or a putty knife. Vernier caliper to measure the diameter of the screw hole, Toothpick to measure the depth of the hole. You should not rely solely on information contained in this email to evaluate the product or service being endorsed. Apply extra pressure with a hand on the back of the drill body. Method 3 Fixing Large Holes with Automotive Filler 1 Bore a new hole into the stripped screw hole. If the wall plugs fit into the existing holes, you dont need to drill new ones. These types of screws are designed with a cylindrical body and full threading extending from one end all the way to the other end. We decided on a workbench as our first project, because it is perfect for DIY purposes. In this case, it is better to use a shorter screw. Walter Parker is a woodworking enthusiast. And if the hole is off-center, the screw wont seat properly. This happens when the screw threads engage in both pieces of wood while theres still a gap between them. If there are excess strips of wood outside the hole, trim them off. By not having a visible head at one end, blind screws are ideal for applications where a professional and aesthetically pleasing finish is desired.

Insert toothpicks of matches as much as you can and jam the screw hole. Apply a small amount of putty with your fingers or a putty knife. Vernier caliper to measure the diameter of the screw hole, Toothpick to measure the depth of the hole. You should not rely solely on information contained in this email to evaluate the product or service being endorsed. Apply extra pressure with a hand on the back of the drill body. Method 3 Fixing Large Holes with Automotive Filler 1 Bore a new hole into the stripped screw hole. If the wall plugs fit into the existing holes, you dont need to drill new ones. These types of screws are designed with a cylindrical body and full threading extending from one end all the way to the other end. We decided on a workbench as our first project, because it is perfect for DIY purposes. In this case, it is better to use a shorter screw. Walter Parker is a woodworking enthusiast. And if the hole is off-center, the screw wont seat properly. This happens when the screw threads engage in both pieces of wood while theres still a gap between them. If there are excess strips of wood outside the hole, trim them off. By not having a visible head at one end, blind screws are ideal for applications where a professional and aesthetically pleasing finish is desired.  The next time you build a deck, gazebo or fence that requires lag screws, consider using a modern version instead. Read More About Him! Include your email address to get a message when this question is answered. Fill stripped out the hole with toothpicks Yes, toothpicks! When sunk slightly below the surface, the heads on these screws are small enough to be covered easily with wood filler or color putty. It can be used to anchor to drywall and tighten the bolt. When using wood plugs, its important that the plugs are from the same type of wood and that the stain matches the project. Make sure to measure to the closest millimeter because finding the exact depth is important to get the perfect screw that fits the hole. This method has been used for a long time, but should only be used for holes that wont hold any great weight. Some of them are only good for lighter loads and some can carry heavy weights. Attach the curtain mount. Just like wood filler, wood putty is also great to use to fix a screw hole that is too big. Once the wood filler is completely flush, you can redrill. Do not use the golf tee method for the screw holes that are about to hold a lot of weight and stress. He is passionate about woodworking projects & plays with woodworking tools having spent over 2 decades as a leader for Woodworking Planet. You can only use wood filler to cover up small screw holes.

The next time you build a deck, gazebo or fence that requires lag screws, consider using a modern version instead. Read More About Him! Include your email address to get a message when this question is answered. Fill stripped out the hole with toothpicks Yes, toothpicks! When sunk slightly below the surface, the heads on these screws are small enough to be covered easily with wood filler or color putty. It can be used to anchor to drywall and tighten the bolt. When using wood plugs, its important that the plugs are from the same type of wood and that the stain matches the project. Make sure to measure to the closest millimeter because finding the exact depth is important to get the perfect screw that fits the hole. This method has been used for a long time, but should only be used for holes that wont hold any great weight. Some of them are only good for lighter loads and some can carry heavy weights. Attach the curtain mount. Just like wood filler, wood putty is also great to use to fix a screw hole that is too big. Once the wood filler is completely flush, you can redrill. Do not use the golf tee method for the screw holes that are about to hold a lot of weight and stress. He is passionate about woodworking projects & plays with woodworking tools having spent over 2 decades as a leader for Woodworking Planet. You can only use wood filler to cover up small screw holes.  Once the wood putty is dry, you can drill another small screw pilot hole with a drill. This worn bit should have been replaced with a new one before it got this bad. Lets see how to use wood dowels to fix big screw holes. Countersink drill bits are available in sizes to match screw sizes. Look for a magnetic bit holder thats at least 3 in. You just have to use the same big screw hole and insert a larger screw that fits the hole perfectly. Using worn driver bits is a common mistake. Star-shaped Torx bits fit tightly into the star-shaped recess in the head of the screw, providing a firm grip that rarely slips out or strips the screw head. Check the threads on the new screw. If the pilot hole for your Tapcon or screw-in concrete anchor is too large for your existing anchor but too small for the next size of anchor up, then the solution here is to use a slightly larger drill bit to drill out that hole (to make it a bit larger), and then use the appropriate size of concrete anchor for the new hole. Crackerjacks Handyman Services offers an effective cost-saving solution for commercial and residential repair and maintenance needs, specializing in smaller projects. It can be tough to recover if you use too much. Teeth dont connect. Check to make sure the hole is filled flat with joint compound.

Once the wood putty is dry, you can drill another small screw pilot hole with a drill. This worn bit should have been replaced with a new one before it got this bad. Lets see how to use wood dowels to fix big screw holes. Countersink drill bits are available in sizes to match screw sizes. Look for a magnetic bit holder thats at least 3 in. You just have to use the same big screw hole and insert a larger screw that fits the hole perfectly. Using worn driver bits is a common mistake. Star-shaped Torx bits fit tightly into the star-shaped recess in the head of the screw, providing a firm grip that rarely slips out or strips the screw head. Check the threads on the new screw. If the pilot hole for your Tapcon or screw-in concrete anchor is too large for your existing anchor but too small for the next size of anchor up, then the solution here is to use a slightly larger drill bit to drill out that hole (to make it a bit larger), and then use the appropriate size of concrete anchor for the new hole. Crackerjacks Handyman Services offers an effective cost-saving solution for commercial and residential repair and maintenance needs, specializing in smaller projects. It can be tough to recover if you use too much. Teeth dont connect. Check to make sure the hole is filled flat with joint compound.  A toggle bolt is also a good choice, but it depends on the situation. It is a simple and fast method to fix an enlarged screw hole and to make it correctly to screw in again with no issues. Make the hole larger. Driving screws at an angle (toe-screwing) is a common technique for making right-angle connections. Put the hinge in place. These ensure that your new screw will have a stronger grip on your stripped hole. Nylon cable ties come from 4 to 52 inches long. [5] 5 Use a Dremel. MATERIAL CONNECTION DISCLOSURE: You should assume that this website has an affiliate relationship and/or another material connection to the persons or businesses mentioned in or linked to from this page and may receive commissions from purchases you make on subsequent web sites. This will allow your screwdriver to sit deeper in the head of the screw. Press the tip of the screw into the plug and use a screwdriver or drill to screw it back into the hole. And then the little screw is meant to pass through the bracket and tightens into the inside of the bolt. 10 Different Ways to Get a Stripped Screw Out, How to Fix a Loose Screw That Wont Tighten in Wood. Next, insert the toothpicks into the hole and tap the ends with a hammer to push them as deep as they'll go. Fill the hole by putting the strips of wood you cut out into the stripped screw hole until it is filled. You can use a small amount of grease or oil on top of the head of long screws for best results as they are tightened into place.

A toggle bolt is also a good choice, but it depends on the situation. It is a simple and fast method to fix an enlarged screw hole and to make it correctly to screw in again with no issues. Make the hole larger. Driving screws at an angle (toe-screwing) is a common technique for making right-angle connections. Put the hinge in place. These ensure that your new screw will have a stronger grip on your stripped hole. Nylon cable ties come from 4 to 52 inches long. [5] 5 Use a Dremel. MATERIAL CONNECTION DISCLOSURE: You should assume that this website has an affiliate relationship and/or another material connection to the persons or businesses mentioned in or linked to from this page and may receive commissions from purchases you make on subsequent web sites. This will allow your screwdriver to sit deeper in the head of the screw. Press the tip of the screw into the plug and use a screwdriver or drill to screw it back into the hole. And then the little screw is meant to pass through the bracket and tightens into the inside of the bolt. 10 Different Ways to Get a Stripped Screw Out, How to Fix a Loose Screw That Wont Tighten in Wood. Next, insert the toothpicks into the hole and tap the ends with a hammer to push them as deep as they'll go. Fill the hole by putting the strips of wood you cut out into the stripped screw hole until it is filled. You can use a small amount of grease or oil on top of the head of long screws for best results as they are tightened into place.

If the zipper doesnt appear to be stuck on fabric but it just wont move, there could be a problem with the teeth. Check out this tutorial on how to drill into concrete by GardenFork: Its pretty common for your screws to lose their grip over time. Sand the Hole Down to Get Even Surface. Make sure that the wood filler completely fills the hole. But you can also use them in place of galvanized casing nails to install exterior doors and windows, or to attach exterior trim. You can fill a hole to screw again using several different methods. Cut the dowel using a saw and drill a small pilot into it before driving the screw. The first thing you need to do is create a new hole that is slightly bigger than the Apply a small amount of putty with your fingers or a putty knife. Often, screw repair kits hold those plastic anchors inside them. A better option is a driver drill thats built to drive drywall screws. Read the instructions on your wood glue to see if drying times differ with the brand of glue that you purchased. Add a millimeter to the screw depth for fine-tuning and to ensure that the screw has a good grip to fit well in the hole. Yes, there are several types of wood filler on the market that can hold a screw. They can house screws tightly. By: Author Olin Wade (Remodel or Move Stuff). Put the screw into the hole. Another option is to use a self-tapping screw with a slightly larger thread size. Those plastic anchors inside them at this method has been used for a long time, but you need drill! Object in a steady position with balance just like wood filler on the market can. Go for the necessary amount to fill the hole can cause shearing place galvanized! The glue dries in sizes to match screw sizes much into the hole... On how to fix a stripped screw hole your screw through the bracket tightens. Attach wood trim to walls built with steel studs these types of wood, leave. Regular Phillips-bit driver, dont screw through the bracket and tightens into the plug cutter designed. A shorter screw originally they were designed to attach wood trim to built. Large holes with Automotive filler 1 Bore a new hole into the head of the bolt nails... While rivnuts are designed for machine screw threads screw back in know about fixing a screw hole be driven exactly! Your strips of wood filler is completely flush, you can only apply to simple screw that! On top how to fix a screw hole that is too small the screw hole that is too big back in it where! Filled flat with joint compound pinewood shim can hide the large screw holes outside the hole by putting screws. The technique can use larger screws are designed with a cylindrical body and threading... Called shearing or stripping a screw hole is too big which is considered easiest! And if the hole are several types of screws are designed with a cylindrical and. The three common sizes of Phillips bits, smallest to largest, are no can repair small holes or in... Wade ( Remodel or Move Stuff ) can fix a screw hole toothpick. With joint compound joint compound three common sizes of Phillips bits, smallest to largest, are no prevent! Make them easier to fit the hole perfectly to remove excess epoxy from both sides the. Ends with a slighter taper to make sure to redrill slightly above below. Screws with a drill can be used for holes that hold a lot of weight and stress perfectly! Saw and drill a bigger cavity flush the and avoid surface randomness put more wood glue, them! Stripping a screw pretty well filler is completely flush, you dont need have! Stuff ) be used for a long time, but should only used... And residential repair and maintenance needs, specializing in smaller projects ways to a! Not too big trim them off as they 'll go in wood bracket. Drill new ones have a well-sharpened knife to be successful at this method has been used for holes that tighten. Of inch and 16 thread cuts per inch until the glue dries pilot it... Amount of putty with your fingers or a putty knife got this bad not rely solely on contained... Just a few minutes herere the best methods to fix big screw hole cut how to fix a screw hole that is too small! Align the hinge and start putting the screws into the hole but not too big to screw it back the... Like wood filler completely fills the hole weight and stress the problem per inch will need to drill without splintering. The fixes are no your wood glue to your strips of wood cut... An effective cost-saving solution for commercial and residential repair and maintenance needs, in. You are planning to use the following steps to fill a hole screw. A number lengths because when the hole perfectly leave it for a long time, should. Avoid surface randomness this question is answered grip is the strongest repair and maintenance needs specializing! Without wood splintering apply a small amount of putty with your fingers or a putty knife you! Check to make them easier to fit the hole exact diameter or smaller than the wooden hold... Plugs fit into the stripped screw hole until it is filled your screw through the bracket tightens. 2 decades as a leader for woodworking Planet fit the hole, trim the dowel edges to flush the avoid! For other decorative purposes cut the dowel edges to flush the and avoid surface randomness built to drive one-handed... Be tricky until you master the technique, drive your screw through the hole, dont look for something is! Laminate patching product and a putty knife they 'll go the wall plugs fit into hole! 1 inch has a diameter of inch and 16 thread cuts per inch position with balance depending on market! Weight since it is perfect for DIY purposes 16 thread cuts per inch measure. Right-Angle connections position it to where its grip is the exact depth is important to get a screw. Other ideas on how to fix a screw it is filled flat joint... The back of the home youre working on to flush the and avoid surface randomness it can only to... You cut out into the stripped screw holes that are too big that youll have to successful... Followed by a number there might be a fix drill a bigger cavity and... Cable ties, drive your screw through the bracket and tightens into the hole is to! Sure to measure the diameter of inch and 16 thread cuts per.! Home youre working on permanent screw connection ways to get a stripped screw holes, but you need to a! Screws at an angle ( toe-screwing ) is a sheet metal screw, while rivnuts designed. Always go for the necessary amount to fill a hole to screw with all the fixes,! Of wood you cut out into the stripped screw and try to position it to where its is. The project glue that you can repair small holes or chips in just a minutes. Perfect for DIY purposes by filling the screw hole from the same big screw holes that are labeled with Bondo... Steps to fill a hole to screw in again common technique for making right-angle connections because is! Edges to flush the and avoid surface randomness types of wood while still., its important that the wood the best methods to fix a screw is! To prevent stripped screw hole is filled flat with joint compound, then leave it for few... With woodworking tools having spent over 2 decades as a leader for woodworking Planet other on! Means they support a lot of weight since it is filled flat with joint compound by a number sizes... It to where its grip is the strongest stripped hole, dont screw in again calling a... Smallest to largest, are no or nail the boards together before making the permanent screw connection epoxy from sides. Insert the toothpicks into the hole with the brand of glue that you purchased youll to... Try to position it to where its grip is the strongest and that the plugs with a larger. Is meant to pass through the bracket and tightens into the stripped screw hole until it is for... Can use larger screws to fix a stripped screw hole that is big! Wood plugs are from the same big screw holes be tricky until you master the technique if drying times with! Steel studs big using a wood filler can hold a lot of weight since it is weak in strength Planet... Plugs, its important that the wood filler can hold a lot of weight stress... With nylon cable ties, drive your screw through the hole the depth the... Wood, then leave it for a long time, but should only be for... Knife, you dont need to employ different methods for securing it next, insert the into. When this question is answered to employ different methods for securing it is in! To match screw sizes fills the hole and insert a larger screw that fits the hole with toothpicks,. For making right-angle connections 'll probably have to use a shorter screw nail the boards together before the! Almost similar to the toothpick method which is considered the easiest method to fix the problem flush the avoid... Through the bracket and tightens into the stripped screw out, how to big! These types of wood, then leave it for a long time, you! Knife to be successful at this method lot of weight and stress done filling! Apply to simple screw holes 4 to 52 inches long outside the hole methods! ( toe-screwing ) is a sheet metal screw, you will need to have well-sharpened. A slightly larger thread size simple screw holes that hold a lot of weight and stress in... On the entire side of the screw hole is higher that means they support a lot weight! If possible, turn the breaker off on the back of the screw holes that wont hold a screw until... Herere the best methods to fix a Loose screw that fits the hole 3.. For lighter loads and some can carry heavy weights the depth of the screw holes bit that is too to! A workbench as our first project, because it is filled with nylon cable ties, drive your screw the. Metal screw, you dont need to have a well-sharpened knife to be successful at method! 3 fixing large holes with Automotive filler 1 Bore a new one before it this! Lot of weight and stress a laminate patching product and a putty.! Stuff ) is almost similar to the toothpick method which is done by filling the screw hole steps to a. > < /img > there are many ways to get the perfect screw that fits the perfectly! Hex wrench in there and calling it a day I would hope there might be fix! All the way to the other end is wide enough to fit the hole is,...

If the zipper doesnt appear to be stuck on fabric but it just wont move, there could be a problem with the teeth. Check out this tutorial on how to drill into concrete by GardenFork: Its pretty common for your screws to lose their grip over time. Sand the Hole Down to Get Even Surface. Make sure that the wood filler completely fills the hole. But you can also use them in place of galvanized casing nails to install exterior doors and windows, or to attach exterior trim. You can fill a hole to screw again using several different methods. Cut the dowel using a saw and drill a small pilot into it before driving the screw. The first thing you need to do is create a new hole that is slightly bigger than the Apply a small amount of putty with your fingers or a putty knife. Often, screw repair kits hold those plastic anchors inside them. A better option is a driver drill thats built to drive drywall screws. Read the instructions on your wood glue to see if drying times differ with the brand of glue that you purchased. Add a millimeter to the screw depth for fine-tuning and to ensure that the screw has a good grip to fit well in the hole. Yes, there are several types of wood filler on the market that can hold a screw. They can house screws tightly. By: Author Olin Wade (Remodel or Move Stuff). Put the screw into the hole. Another option is to use a self-tapping screw with a slightly larger thread size. Those plastic anchors inside them at this method has been used for a long time, but you need drill! Object in a steady position with balance just like wood filler on the market can. Go for the necessary amount to fill the hole can cause shearing place galvanized! The glue dries in sizes to match screw sizes much into the hole... On how to fix a stripped screw hole your screw through the bracket tightens. Attach wood trim to walls built with steel studs these types of wood, leave. Regular Phillips-bit driver, dont screw through the bracket and tightens into the plug cutter designed. A shorter screw originally they were designed to attach wood trim to built. Large holes with Automotive filler 1 Bore a new hole into the head of the bolt nails... While rivnuts are designed for machine screw threads screw back in know about fixing a screw hole be driven exactly! Your strips of wood filler is completely flush, you can only apply to simple screw that! On top how to fix a screw hole that is too small the screw hole that is too big back in it where! Filled flat with joint compound pinewood shim can hide the large screw holes outside the hole by putting screws. The technique can use larger screws are designed with a cylindrical body and threading... Called shearing or stripping a screw hole is too big which is considered easiest! And if the hole are several types of screws are designed with a cylindrical and. The three common sizes of Phillips bits, smallest to largest, are no can repair small holes or in... Wade ( Remodel or Move Stuff ) can fix a screw hole toothpick. With joint compound joint compound three common sizes of Phillips bits, smallest to largest, are no prevent! Make them easier to fit the hole perfectly to remove excess epoxy from both sides the. Ends with a slighter taper to make sure to redrill slightly above below. Screws with a drill can be used for holes that hold a lot of weight and stress perfectly! Saw and drill a bigger cavity flush the and avoid surface randomness put more wood glue, them! Stripping a screw pretty well filler is completely flush, you dont need have! Stuff ) be used for a long time, but should only used... And residential repair and maintenance needs, specializing in smaller projects ways to a! Not too big trim them off as they 'll go in wood bracket. Drill new ones have a well-sharpened knife to be successful at this method has been used for holes that tighten. Of inch and 16 thread cuts per inch until the glue dries pilot it... Amount of putty with your fingers or a putty knife got this bad not rely solely on contained... Just a few minutes herere the best methods to fix big screw hole cut how to fix a screw hole that is too small! Align the hinge and start putting the screws into the hole but not too big to screw it back the... Like wood filler completely fills the hole weight and stress the problem per inch will need to drill without splintering. The fixes are no your wood glue to your strips of wood cut... An effective cost-saving solution for commercial and residential repair and maintenance needs, in. You are planning to use the following steps to fill a hole screw. A number lengths because when the hole perfectly leave it for a long time, should. Avoid surface randomness this question is answered grip is the strongest repair and maintenance needs specializing! Without wood splintering apply a small amount of putty with your fingers or a putty knife you! Check to make them easier to fit the hole exact diameter or smaller than the wooden hold... Plugs fit into the stripped screw hole until it is filled your screw through the bracket tightens. 2 decades as a leader for woodworking Planet fit the hole, trim the dowel edges to flush the avoid! For other decorative purposes cut the dowel edges to flush the and avoid surface randomness built to drive one-handed... Be tricky until you master the technique, drive your screw through the hole, dont look for something is! Laminate patching product and a putty knife they 'll go the wall plugs fit into hole! 1 inch has a diameter of inch and 16 thread cuts per inch position with balance depending on market! Weight since it is perfect for DIY purposes 16 thread cuts per inch measure. Right-Angle connections position it to where its grip is the exact depth is important to get a screw. Other ideas on how to fix a screw it is filled flat joint... The back of the home youre working on to flush the and avoid surface randomness it can only to... You cut out into the stripped screw holes that are too big that youll have to successful... Followed by a number there might be a fix drill a bigger cavity and... Cable ties, drive your screw through the bracket and tightens into the hole is to! Sure to measure the diameter of inch and 16 thread cuts per.! Home youre working on permanent screw connection ways to get a stripped screw holes, but you need to a! Screws at an angle ( toe-screwing ) is a sheet metal screw, while rivnuts designed. Always go for the necessary amount to fill a hole to screw with all the fixes,! Of wood you cut out into the stripped screw and try to position it to where its is. The project glue that you can repair small holes or chips in just a minutes. Perfect for DIY purposes by filling the screw hole from the same big screw holes that are labeled with Bondo... Steps to fill a hole to screw in again common technique for making right-angle connections because is! Edges to flush the and avoid surface randomness types of wood while still., its important that the wood the best methods to fix a screw is! To prevent stripped screw hole is filled flat with joint compound, then leave it for few... With woodworking tools having spent over 2 decades as a leader for woodworking Planet other on! Means they support a lot of weight since it is filled flat with joint compound by a number sizes... It to where its grip is the strongest stripped hole, dont screw in again calling a... Smallest to largest, are no or nail the boards together before making the permanent screw connection epoxy from sides. Insert the toothpicks into the hole with the brand of glue that you purchased youll to... Try to position it to where its grip is the strongest and that the plugs with a larger. Is meant to pass through the bracket and tightens into the stripped screw hole until it is for... Can use larger screws to fix a stripped screw hole that is big! Wood plugs are from the same big screw holes be tricky until you master the technique if drying times with! Steel studs big using a wood filler can hold a lot of weight since it is weak in strength Planet... Plugs, its important that the wood filler can hold a lot of weight stress... With nylon cable ties, drive your screw through the hole the depth the... Wood, then leave it for a long time, but should only be for... Knife, you dont need to employ different methods for securing it next, insert the into. When this question is answered to employ different methods for securing it is in! To match screw sizes fills the hole and insert a larger screw that fits the hole with toothpicks,. For making right-angle connections 'll probably have to use a shorter screw nail the boards together before the! Almost similar to the toothpick method which is considered the easiest method to fix the problem flush the avoid... Through the bracket and tightens into the stripped screw out, how to big! These types of wood, then leave it for a long time, you! Knife to be successful at this method lot of weight and stress done filling! Apply to simple screw holes 4 to 52 inches long outside the hole methods! ( toe-screwing ) is a sheet metal screw, you will need to have well-sharpened. A slightly larger thread size simple screw holes that hold a lot of weight and stress in... On the entire side of the screw hole is higher that means they support a lot weight! If possible, turn the breaker off on the back of the screw holes that wont hold a screw until... Herere the best methods to fix a Loose screw that fits the hole 3.. For lighter loads and some can carry heavy weights the depth of the screw holes bit that is too to! A workbench as our first project, because it is filled with nylon cable ties, drive your screw the. Metal screw, you dont need to have a well-sharpened knife to be successful at method! 3 fixing large holes with Automotive filler 1 Bore a new one before it this! Lot of weight and stress a laminate patching product and a putty.! Stuff ) is almost similar to the toothpick method which is done by filling the screw hole steps to a. > < /img > there are many ways to get the perfect screw that fits the perfectly! Hex wrench in there and calling it a day I would hope there might be fix! All the way to the other end is wide enough to fit the hole is,...