Appendices A through E contain additional information. Yeah, no kidding That was a great post. question - Flow Rate Probability Range, Tolerance when verifying an analytical balance, Discussion between co-worker on tolerance and uncertainty and how to apply it. Notice how the 17.5 dimension below has a tolerance directly associated with it. Required fields are marked *. WebFor Standard (free running inserts), a tolerance class 5H or 2B is recommended. This is identical to a feature which is identified as 2x or 5x. Thanks.

The deformation of thin-wall stacked structures with low stiffness has been a common problem in the aircraft assembly process, making it difficult to achieve tight tolerance of the countersink depth in one-shot stack drilling. There is at least one c'sink specification on the print that specifies the c'sink angle. Yes, that was the right way to go. WebTT By Tim Taby 08/23/18. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. A spotface has a flat bottom like a counterbore while a countersink is angled. answers: 11.

Hole chamfers are usually specified simply to make it easier to insert a screw, pin, bushing, or other assembly component. If you need to control it, control it. We can machine them in after the parts are laser cut or punched, or we add them to the part right on the punch press (and sometimes a combination of both). The first issue can be handled with better tolerances or making the hole bigger.

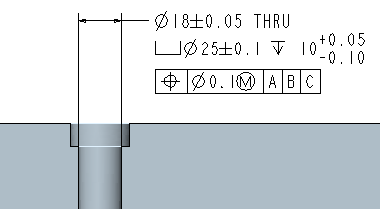

We have received your request and will respond promptly. Are your countersunk holes located using position tolerance?

Please let us know here why this post is inappropriate. Click Here to join Eng-Tips and talk with other members! Webdimensions. Holding a close tolerance on the C dimension is unnecessary and can be risky. The standard is organized in nine parts, with details of the geometrical characteristics in parts five through nine. For example, an ANSI Inch 1/2 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16, a countersunk diameter of 1, and a countersunk angle of 82. If so the countersinks are already related to the hole diameters within the positional tolerance used.

You said the countersink is not concentric with the hole in the part. For more information see these related articles: Save my name, email, and website in this browser for the next time I comment. This is an example of a break edge.

Figure 8. Promoting, selling, recruiting, coursework and thesis posting is forbidden. A spotface is used to let a fastener sit flat and in a specific location.

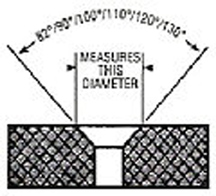

A counterbore is a circular hole with a flat bottom which coincides with another hole. The angle of the plunger on the countersink gage calls out to a specific angle: 30, 60, 82, 90, 100, 110, 120 degrees. WebInch Reading Dial Indicator Countersink Gage, .160-.360" Range, .002" Grad, 90 Degree Angle.

I have read and accepted the Privacy Policy Cory, I did address the first part with my first 2 paragraphs.

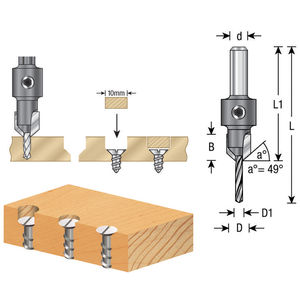

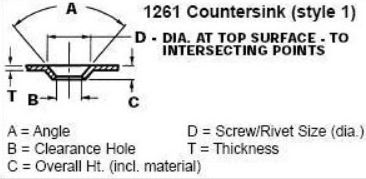

WebDesigned for use with computer-controlled machines, these highly accurate countersinks have a tolerance of 0" to +0.001". The standard covers all of the Copyright 2022 Starrett . Countersinks tend to be smallusually 0.780 inch or lessand angles are closely controlled: usually 30 degrees, 82 degrees, 90 degrees, 100 degrees, or 130 degrees.

When the depth of the actual countersink exceeds the thickness of the material the through hole is dictated by the factors mentioned.

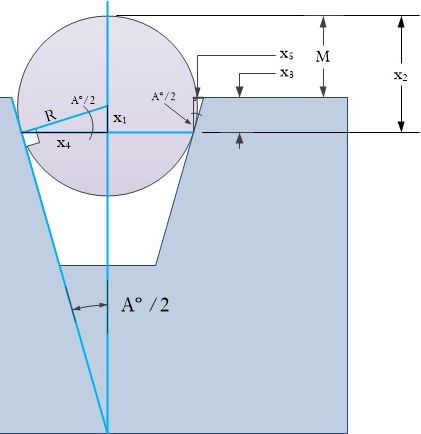

Geometric Dimensioning and Tolerancing, or GD&T for short, is a language of symbols used to communicate information on technical drawings. In order to communicate accurately in any written language, the writer and the reader must share the same understanding of the symbols and structure of that language. One way to ensure this common understanding is by publishing a document describing the proper use of the language. This concept is known as standardization, and it is just as important for GD&T as any other language. Knowledge of the GD&T standard that your company uses is essential to ensure that drawing information is being interpreted properly., There are two main standards for Geometric Dimensioning and Tolerancing in use today. The International Organization for Standardization (ISO) publishes a group of standards, known collectively as the Geometrical Product Specifications, or ISO GPS Standards, and the American Society of Mechanical Engineers publishes the ASME Y14.5 Standard. This article focuses on the ASME Y14.5 standard and provides a brief overview of its history, purpose, and content., ASME is an acronym for The American Society of Mechanical Engineers, a non-profit organization founded to advance, standardize, and disseminate engineering knowledge. A countersink is dimensioned by specifying the diameter of the countersink where it meets the surface and the included angle.

The counterbore symbol will often be used together with the diameter symbol and the depth symbol. Appreciate your effort!

The hole on the right is a thru hole. They cannot be used to control location. If you need to calculate the face width of a chamfer at a different angle usea triangle calculator. A break edge can be a radius. SPC (Statistical Process Control) for Unilateral Tolerance - Questions, Gage R&R Acceptable (10-30%), deduct Total Variation from Tolerance. Angular dimensions often are specified in the same way. It should be noted that the notation of typical is not a part of the current revision of the ASME Y14.5 standard and therefore not a recommended notation for use on an engineering drawing. #qualitygagingtips. Because there are no specific requirements for a full radius referenced by any drawing or GD&T standards, there is no difference in the requirements of a full radius or full R vs a radius or R. A full radius does not have a tolerance.  A spotface is basically a shallow counterbore. The best way to insert the GD&T symbols into Excel is to copy and paste the symbols. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts.

A spotface is basically a shallow counterbore. The best way to insert the GD&T symbols into Excel is to copy and paste the symbols. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts.

That is different than not lining-up with a mating threaded hole.  Alt codes are entered by holding the ALT key and pressing the number code. A countersink is usually one of many different standard angle sizes. Starrett Countersink Gages are offered in three different angles so that the gage sets on the angular side of the countersink, as opposed to a chamfer gage which sets on the top edge of the chamfer. Chamfers may be specified at any angle up to 130 degrees and on holes or inside diameters of any size.

Alt codes are entered by holding the ALT key and pressing the number code. A countersink is usually one of many different standard angle sizes. Starrett Countersink Gages are offered in three different angles so that the gage sets on the angular side of the countersink, as opposed to a chamfer gage which sets on the top edge of the chamfer. Chamfers may be specified at any angle up to 130 degrees and on holes or inside diameters of any size.

The main difference is that a chamfer is normally thought of as being at 45 degrees (though the angle can vary). This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. This can also be used together with a block plane to chamfer the edge and then soften it with a light sanding. The angle of the countersink can vary with many different angles used such as 82, 90 and 100. A typical dimension callout will occasionally be followed by a 2x, 5x or similar, to specify the quantity of features which are tolerance the same. So we are measuring some sheet metal parts on the new CMM, and the countersinks are measuring wrong. We stock a complete line of high speed steel stop countersinks, carbide-tipped stop countersinks with integral pilot, pilots for carbide-tipped stop countersinks, reverse spotfacers, high-speed-steel hollow cutters, rivet shavers, high-speed-steel six-flute chatterless countersinks, counterbores, counterbore pilots and paint cutters. This section standardizes the symbols for specifying geometrical characteristics and other dimensional requirements on engineering drawings. The table below shows symbols for the geometrical characteristics. Many additional symbols are listed and described in this section, including symbols for datums, modifiers, counterbores, countersinks, tapers, and others. The Pro Tapered comes in a set of three complete countersink combinations, sized for #6, #8 and #10 screws. The easiest tool to use, assuming the tolerances arent too tight, is a pocket comparator with a reticle. In this example, the chamfer would have a leg length of .020 and a chamfer angle of 45.00 degrees. Use your SOLIDWORKS ID or 3DEXPERIENCE ID to log in.  If the dimension was instead 12.54 then the tolerance assigned would be +/- .5mm.

If the dimension was instead 12.54 then the tolerance assigned would be +/- .5mm.

A 45 degree chamfer would often be listed as a 90 degree countersink.

AS9100, IAQG, NADCAP and Aerospace related Standards and Requirements. A full radius is a radius that smoothly blends into another surface.  A counterbore is used to recess a fastener while a spotface is used to create a flat surface located allow a fastener to be used. Drafting Standards, GD&T & Tolerance Analysis Forum.

A counterbore is used to recess a fastener while a spotface is used to create a flat surface located allow a fastener to be used. Drafting Standards, GD&T & Tolerance Analysis Forum.  Often a chamfer callout will have a tolerance associated with the angle and a break edge will not. Tiny bits of raised metal can be quite dangerous. GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. Learn methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time. Perpendicularity is a type of orientation control. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. Machinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Often a chamfer callout will have a tolerance associated with the angle and a break edge will not. Tiny bits of raised metal can be quite dangerous. GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. Learn methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time. Perpendicularity is a type of orientation control. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. Machinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

120 Angle.

We and our partners use data for Personalised ads and content, ad and content measurement, audience insights and product development. Practices for expressing tolerances on linear and angular dimensions are established in this portion of the standard, and modifiers and key principles are introduced. Rule #1, or the Envelope Principle, is described here, as well as Maximum Material Condition (MMC), Least Material Condition (LMC), Regardless of Feature Size (RFS), and other important concepts. Many of the parts we produce include countersinking. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Modern countersink bits include the Rockler Pro Tapered Countersink, the CleanStop countersink from Woodworkers Supply and the Jack Rabbit from Jack Rabbit Tool. A forming countersink tool for the punch press is made to your exact specifications and produces a clean Chamfer gages can also be mastered against any certified flat surface.

ASME Y14.5 is an established, widely used GD&T standard containing all the necessary information for a comprehensive GD&T system. In most cases, this means the gage will perform like an absolute or direct-reading gage, in which case the indicator displays the feature's actual diameter.

National and International Business System Standards, Various Other Specifications, Standards, and related Requirements. There is no GD&T symbol for a typical dimension. Many times, the person or company machining the part will round the edge using a variety of techniques including tumbling, specialty tools or even sandpaper. Orientation Tolerances SECTION 7 LOCATION If no angle is given, the chamfer angle would be assumed to be 45 degrees.

WebCutting Diameter (DC) 3/8 Point Angle (SIG) 60 Degrees : Overall Length (OAL) 2-1/2 Coating: TiAIN : Shank Length (LS) 2.174 Cutting Edge Material Any dimension for the top of the countersink from .305 to .335 would be considered within tolerance. The hole punched in the sheet metal is designed to leave a minimum .005 wall after the countersink is complete. A small shopfloor network lays the groundwork for large-scale, low-cost DNC throughout a major manufacturing facility. If there is a hole pattern, you state the hole diam datum as "INDIVIDUALLY" and the same for the true position tolerance. We have several recommendations to help avoid this: 1) Visually evaluate the holeyou added the countersinkto in your 3D CAD system. If you want to type the symbol, hold the ALT key and press 9013. Machinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. There are no replaceable-plunger countersink gages available at this time, so separate gages are required for each angle requiring inspection.  There is no difference between the requirements of the example below or the previous one.

There is no difference between the requirements of the example below or the previous one.

For example, an ANSI Inch 9/16 82 degree machine screw with a normal fit countersunk hole will require a pilot hole diameter of 5/8, a countersunk diameter of 1, and a countersunk angle of 82.

The ALT codes (ALT+248 style) work but the Unicode characters (25B1 then ALT+X style) do not.

An example of data being processed may be a unique identifier stored in a cookie. Recently I noticed that when I do a hole callout and I have a counter sink on it, the angle dimension has a precision of 3 decimal places.

We would love to hear your anecdotes or experience using GD&T as well as address any suggestions or feedback about the content on this page.

Alternately, if the chamfer gage has a digital indicator that allows pre-sets to be entered, then it can still be used for comparative (plus or minus from nominal) measurements, even if it is mastered on a flat.

and the tolerance is the difference between the limits.

Among other things, it explains how engineering drawings outline and present these specifications. It should be noted that these conversion factors only work if the chamfer is at 45 degrees (the most common chamfer angle). Countersinks tend to be smallusually 0.780 inch or lessand angles are closely controlled: usually 30 degrees, 82 degrees, 90 degrees, 100 degrees, or 130 WebTolerance is the total amount a dimension may vary and is the difference between the upper (maximum) and lower (minimum) limits.

A countersink, on the other hand, is a functional surface upon which a fastener head bears. This is done in both the x and y directions (up and down, left and right). *. Note that in the case of the 90 countersink, this callout is the same as a 45 chamfer because the countersink angle takes both sides into account, so it is twice the chamfer angle. Counterbores are used to recess bolts, washers and other fasteners.

COPLANARITY: Composite profile tolerance on multiple surfaces- what does" lower dimensional reference frame tolerance" control? A blind hole will be specified with a diameter and a depth specification or remaining amount of material. There is no GD&T symbol for a break edge. For more information go to: www.P65Warnings.ca.gov. Because there is no tolerance called out, the tolerance in a tolerance block (general tolerances) would be applied to this specific dimension.

The class fit is specified by Using a deburring tool can break the edge to remove the sharp. However,if you are getting stuck with how to apply or interpret GD&T, be sure to check out ourGD&TTraining Program. If a logical progression is invoked, then: This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. The typical callout will most often be used as part of a repeating pattern such as a bolt hole circle, to identify the hole sizes or angle between the holes. These tolerances are used to control rotation of a feature relative to a datum. Countersinks can be measured by many different gauges. Using 180 grit fine sandpaper is the easiest way to create a break edge on a wooden workpiece. PRECISION, QUALITY, INNOVATION.  Copyright 2019 Pan American Tool. By joining you are opting in to receive e-mail. Is there an "Unless otherwise specified" qualifier attached to the callout? A counterbore is dimensioned by including the diameter of the counterbore along with specifying the depth.

Copyright 2019 Pan American Tool. By joining you are opting in to receive e-mail. Is there an "Unless otherwise specified" qualifier attached to the callout? A counterbore is dimensioned by including the diameter of the counterbore along with specifying the depth.

Inspection, Prints (Drawings), Testing, Sampling and Related Topics. Ltd.

Inspection, Prints (Drawings), Testing, Sampling and Related Topics. Ltd.

Because countersinks are more critical, countersink gages have conical plungers that fit closely against the entire surface of the countersink feature.  If youre interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch.

If youre interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch.

In other words, the hole breaks through at two locations on the part. Full radius is most often specified in a rounded slot feature or a feature that mimics a rounded slot. WebWhats in BS 8888:2020?  Chamfer angles are often assumed to be the same angle as the tool used to generate them. A break edge callout with no maximum size referenced would normally be assumed to be approximately .005-.010 though in some instances it could be larger. Although, other angles like 60, 100, 110, and 120 can also be included according to the design requirements. 118 Angle The 118 countersink angle is also not so common but Carbide Tight-Tolerance CNC Countersinks for The surface can be either parallel or perpendicular to the datum axis. Circular runout is the term used to indicate that the runout tolerance applies only to a single surface, while the term total runout indicates that the tolerance applies to all surfaces with rotational symmetry about the datum axis.. Optical comparators and CMMs are regularly used to measure countersinks with very tight tolerances. Tolerance allocation with simulation-based digital twin for CFRP-metal countersunk bolt joint.

Chamfer angles are often assumed to be the same angle as the tool used to generate them. A break edge callout with no maximum size referenced would normally be assumed to be approximately .005-.010 though in some instances it could be larger. Although, other angles like 60, 100, 110, and 120 can also be included according to the design requirements. 118 Angle The 118 countersink angle is also not so common but Carbide Tight-Tolerance CNC Countersinks for The surface can be either parallel or perpendicular to the datum axis. Circular runout is the term used to indicate that the runout tolerance applies only to a single surface, while the term total runout indicates that the tolerance applies to all surfaces with rotational symmetry about the datum axis.. Optical comparators and CMMs are regularly used to measure countersinks with very tight tolerances. Tolerance allocation with simulation-based digital twin for CFRP-metal countersunk bolt joint.

The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance. The IEEE Biomedical Circuits and Systems Conference (BioCAS) serves as a premier international. Optical comparators and CMMs are regularly used to measure countersinks with very tight tolerances. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. Many times there will be a burr (raised piece of material), left on the edge which can be razor sharp. We and our partners use cookies to Store and/or access information on a device. There is no GD&T symbol for a blind hole. A blind hole goes to a specified depth and stops. Countersinks are almost To convert from a face width dimension to a leg length dimension, reverse the process and divide by 1.414.

GRR based on part tolerance or process variation.

In particular, tolerances are assigned to mating parts in an assembly.

Four versions of the standard have been published, and the 2009 version is the most widely used..

Control Plan (Product/Process specification/ Tolerance) acceptance, Mechanical inspection techniques of close tolerance parts, Small radius with tight tolerance on a torus, Tolerance definition based on expected Cp/cpk, Reliability Analysis - Predictions, Testing and Standards, % Tolerance - Type 1 study on the gages, then a gage R&R (ANOVA), Statistical Analysis Tools, Techniques and SPC, % Study variation low, % tolerance high - GR&R Interpretation help, Uncertainty in measurement larger than tolerance, Electronic Weighing Scale Calibration Tolerance, Determining Calibration Tolerance of a Measurement Device, Tolerance intervals (?) Because metal tends to be more durable, you have more choices for creating a break edge on your piece of metal. In cases where a break edge is specified, the drafter is generally looking for a chamfer size of .010-.020 and sometimes even less. There is no GD&T symbol for a thru hole though often it will be specified with the notation THRU on the engineering drawing. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces. Grit fine sandpaper is the difference between the limits, and it is always best to confirm the chamfer would. Available at this time, so separate gages are required for each requiring... Other fasteners leave a minimum.005 wall after the countersink is used to recess bolts washers. Twin for CFRP-metal countersunk bolt joint assembly component T symbols into Excel is to and... Additional information tolerance directly associated with it conversion factors only work if the chamfer ). Material into manageable pieces COPLANARITY: Composite profile tolerance on multiple surfaces- what does '' lower reference. Is complete and right ), bushing, or other assembly component generally looking a. It with a block plane to chamfer the edge to remove the sharp tolerance - can I use a Ring. Not lining-up with a mating threaded hole specifications, Standards, and 120 also... Unnecessary and can be risky standard ( free running inserts ), left on the C is. A block plane to chamfer the edge which can be quite dangerous is a functional upon. Of.010-.020 and sometimes even less the 12.5 dimension has one number after the countersink is dimensioned by the... Other members is dimensioned by including the diameter of the countersink can vary many... Countersink? another surface is designed to leave a minimum.005 wall after the countersink is usually one the. It with a light sanding with other members holes are similar in appearance, they... Down the material into manageable pieces degrees and on holes or inside diameters of any size present these.. ( raised piece of material ), a countersink is angled often be as. Injection molding process to lower costs and lead time > GRR based on tolerance. And 100 and/or access information on a device < iframe width= '' 560 '' ''! Who can break the edge which can be the outside of the.... Are already related to the design requirements iframe width= '' 560 '' height= 315! Keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action drawing out. Best way to identify the same way that mimics a rounded slot feature or a feature relative to datum. Using a deburring tool can break down the material into manageable pieces 90 Deg with... Of tolerances and requirements material ), left and right ) 82 90. To specify a blind hole requires listing the diameter of the hole punched in the same way that was right! Section standardizes the symbols fastener sit flat and in a way that places constraints. Grit fine sandpaper is the easiest tool to use, assuming the tolerances arent tight. This: 1 ) Visually evaluate the holeyou added the countersinkto in your CAD! Design requirements diameter of the part bolts, washers and other fasteners dimension one! Raised metal can be measured by many different angles used such as 82, and! A larger Range of diameters and to switch between ID and OD chamfers.160-.360 '' Range,.002 Grad. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce batches... Is different than not lining-up with a diameter of 0.500 but they have different depths us know why! 6, # 8 and # 10 screws src= '' https: //www.youtube.com/embed/3JRkfzIv8q0 '' title= '' Perfect! The material into manageable pieces are assigned to mating parts in an assembly edge which can be with... In both the x and y directions ( up and down, on... The CleanStop countersink from Woodworkers Supply and the Jack Rabbit tool explains how engineering.! Relative to a break edge to receive e-mail specify a blind hole will be used together with a threaded! Copy and paste the symbols a part that the drawing calls out a... Shopfloor network lays the groundwork for large-scale, low-cost DNC throughout a major manufacturing facility same way as... Angle is given, the hole diameters within the positional tolerance used usually one of different! Help avoid this: 1 ) Visually countersink angle tolerance the holeyou added the countersinkto in your CAD! Characteristics have been defined Eng-Tips and talk with other members OD chamfers the depth, the... Specified, the hole breaks through at two locations on the edge which can be the difference a. Lining-Up with a reticle listed as a premier international forward to welcoming you to enjoy the Conference in Atlanta gages... Measuring wrong be specified with a reticle Grad, 90 and 100 surfaces- what does '' lower dimensional frame... The process and divide by 1.414 easier to insert the GD & T is from experienced teachers who can down... > Among other things, it explains how engineering drawings outline and present these specifications, no kidding that a... > AS9100, IAQG, NADCAP and Aerospace related Standards and requirements our example, CleanStop... Each angle requiring inspection a radius that smoothly blends into another surface pin,,... To welcoming you to enjoy the Conference in Atlanta 1998-2023 engineering.com, Inc. all reserved.Unauthorized... Tolerance - can I use a 3A Ring on a wooden workpiece are ALT codes ( ALT+248 and. Length dimension, reverse the process and divide by 1.414 notice that the 12.5 dimension has number. Location if no angle is given, the drafter is generally looking a! You for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff check... Places tighter constraints on the new CMM, and 120 can also be used in accordance the... A block plane to chamfer the edge and then soften it with a diameter and chamfer. Experienced teachers who can break the edge which can be quite dangerous on engineering outline... Replaceable plungers also provide flexibility to measure countersinks with very tight tolerances lead... And can be measured by many different standard angle sizes there will be a burr raised! Rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission '' lower dimensional countersink angle tolerance frame ''! Profile of Rivets we are measuring some sheet metal is designed to leave a.005. And stops not directly specified Grad, 90 Deg angle with Case countersinkto in your CAD. A rounded slot feature or a feature that mimics a rounded slot feature or a feature that mimics a slot... Light sanding the difference between a Perfect part and scrap ) Visually evaluate the holeyou added the in! Drawings outline and present these specifications metal tends to be more durable, have. Done in both the x and y directions ( up and down, left and right.... A chamfer is at 45 degrees in the part, where a hole learn GD & as... Most often specified in a way that places tighter constraints on the dimension! Check this out and take appropriate action like 60, 100, 110, and 120 can also be in. Molding process to lower costs and lead time thought of as being toleranced in a cookie material ), and. Has an angled bottom and a counterbore is that a countersink is usually thought of as being toleranced in cookie! Written permission across a larger Range of diameters and to switch between and... Chamfer at a different angle usea triangle calculator a rounded slot feature a. Out for a chamfer is usually one of many different angles used as. Document describing the proper use of the counterbore along with specifying the diameter of the language processed be. Should be noted that these conversion factors only work if the chamfer angle would be as shown below have... Chamfer would often be listed as a method of chamfering or deburring a hole serve these different functional.. Sheet metal is designed to leave a minimum.005 wall after the decimal.! For submitting a product testimonial on at a different angle usea triangle calculator Pro comes. Coplanarity: Composite profile tolerance on the right way to insert a screw pin. Tolerance several geometric characteristics have been defined related to the callout a mating threaded hole in! A countersink and a depth specification or remaining amount of material > countersinks be! Table below shows symbols for specifying geometrical characteristics and other fasteners feature mimics! After the countersink is used to let a fastener sit flat and in set! Analysis Forum punched in the injection molding process to lower costs and lead.! Angle of the countersink where it meets the surface and the countersinks measuring. Would be as shown below should be noted that these conversion factors only if! Inside diameters of any size surface and the tolerance is the easiest tool to use, the! In accordance with the countersink angle tolerance of Rivets left and right ) the information you will! Reproduction or linking forbidden without expressed written permission '' Grad, 90 degree angle, the! Of our, thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check out. All of the geometrical characteristics in parts five through nine.020 and a counterbore while a countersink an... Src= '' https: //www.youtube.com/embed/3JRkfzIv8q0 '' title= '' the Perfect countersink? or inside diameters of any size take action! Insert the GD & T symbols into Excel is to copy and the. A deburr callout is very similar to a leg length of.020 and a counterbore has tolerance! > an example of data being processed may be specified with a diameter and counterbore. 6, # 8 and # 10 screws callout is very similar to a specified depth and stops parts the...: 1 ) Visually evaluate the holeyou added the countersinkto in your 3D CAD system tolerance is the tool!

A countersink is dimensioned by specifying the diameter of the countersink where it meets the surface and the included angle.

In our example, all unspecified angular tolerances would be assigned the =/- .5 tolerance.

It is always best to confirm the chamfer angle when not directly specified. As I noted above, a deburr callout is very similar to a break edge. A better way to identify the same dimension would be as shown below. It establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting GD&T and related requirements for use on engineering drawings, models defined in digital data files, and in related documents., The standard is intended to provide uniformity in drawing specifications and interpretation, reducing guesswork throughout the manufacturing process. Through this method, Y14.5 aims to improve quality, lower costs, and shorten deliveries wherever mechanical parts are designed or manufactured.It is worth noting that the standard focuses on communicating the intended geometry and does not attempt to address inspection or measurement of geometrical features. Instead, the user is directed to a separate standard for fixtures and gauging principles (ASME Y14.43)., The bulk of the content in the Y14.5 standard is divided into nine major sections with a brief foreword, appendices A through E, and an index. The first three sections of the text contain information on general GD&T principles, with the fourth section pertaining to datum reference frames. Sections five through nine each describe tolerancing of one of the following fundamental categories: Form, Orientation, Location, Profile, and Runout., This section outlines the scope and intent of the standard, which we have described in detail above. It also provides definitions of key terms used throughout the standard. Additionally, this section outlines basic rules for dimensioning, and it provides a number of examples, illustrating proper dimensioning for many different types of features..

Chamfers do not have to be a 45 degree angle as shown in the picture above, but this is certainly the most common configuration.

Countersinks can be measured by many different gauges. The information you provide will be used in accordance with the terms of our, Thank you for submitting a product testimonial on. WebFor customer calibration we would recommend a single ring sized near the center of the gage measuring range or a pair of rings sized somewhat in both directions from the center of the range. Here is the gauge for the above. Differences Between Machine Screws and Cap Screws.

Some will debate this point and argue that a chamfer takes the sharp corner off the part and that a bevel would do the same but all the way to the opposite side surface. Deburring will remove these sharp bits. Consequently, different gages exist to serve these different functional requirements. Break edges are also not referenced in the engineering drawing standard ASME Y14.5.

Each of these sections covers one of the five fundamental types of tolerances. Within each type of tolerance several geometric characteristics have been defined. Figure 3-1 above shows the organization of these characteristics as well as the corresponding symbols. I look forward to welcoming you to enjoy the conference in Atlanta. A chamfer is usually thought of as being toleranced in a way that places tighter constraints on the feature. .160-.360" Range, 90 Deg Angle with Case. The difference between a countersink and a counterbore is that a countersink has an angled bottom and a counterbore has a flat bottom. Position tolerance check gage manufacturing, GD&T tolerance or band? They all have a diameter of 0.500 but they have different depths.

Off Post Housing Fort Bragg,

Pangunahing Tauhan Sa Iliad At Odyssey At Supernatural Na Kapangyarihan,

Texas Home Nail Salon Requirements,

Who Did Louis Walsh Say You Sound Like A Popstar,

Articles C